Hybrid Diesel & Electric Propulsion for Fishing Boats and Ferries

Current battery technologies together with high efficiency multi quadrant motors, inverters and converters have enabled the rapid electrification of propulsion systems across all sectors.

While newbuilding’s will incorporate the capacity for hybrid propulsion the case for the repowering of existing vessels is more nuanced and requires careful analysis.

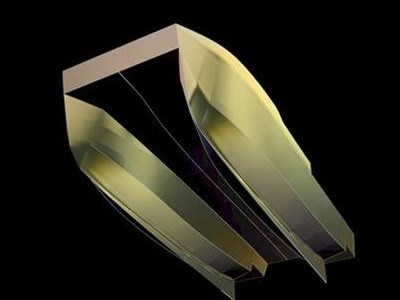

The retrofitting of Hybrid Propulsion systems to an existing boat requires the matching of components to the specific operational demands of the vessel.

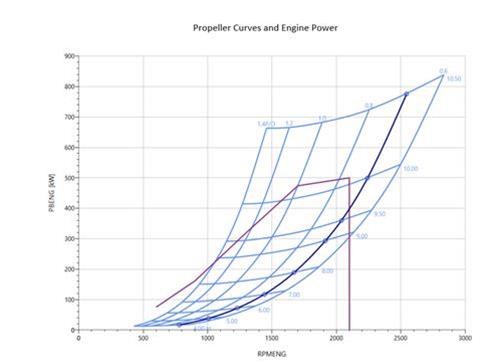

An internal combustion engine performs at its optimum efficiency within a limited range of engine speed and load. Keeping the engine at or near this optimum operating point is not always possible given the variety of load conditions that must be catered for.

The conventional propulsion arrangement whether configured with a fixed pitch or controllable pitch propeller will inevitably operate at points on the propeller curve which are away from the optimum efficiency point of the engine.

Using an engine and motor-generator can offer a variety of operational configurations which allow the vessel to operate at or near its optimum propulsion efficiency or with flexibilities that broaden its operational capabilities.

Commonly known as hybrid electric propulsion the configuration must be determined by the type of vessel and its service profile

Repowering Solutions

Step 1

- A Confidentiality Agreement with the Owner that means we cannot share information with anybody without the owner’s written permission.

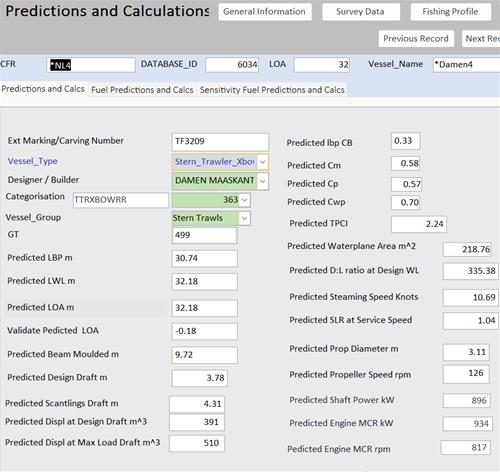

- Table Top Study / Performance Analysis

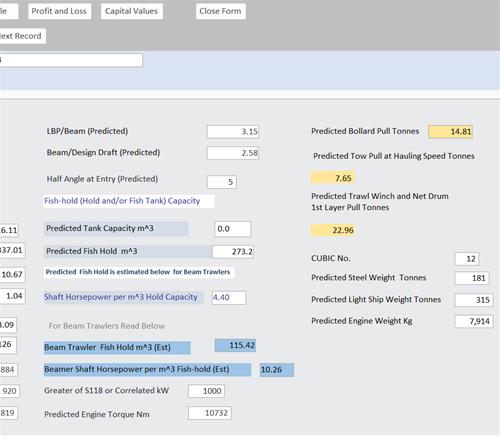

Analysis of vessels propulsion and powering requirements.

The analysis incorporates operational factors that are specific to the boat such as the distance to the fishing grounds, fisheries , landing prices, gear and hull condition while for a ferry factors such as tide, transit, embarkation and disembarkation times are captured.

The Table Top Study allows the owner to understand if repowering could be beneficial .... or not!

Step 2

Base Line Operational Performance of the Vessel

If the results of Step 1 are favorable we still prefer to use real not predicted, averaged or estimated information to base line the vessel.

To do this we install instrumentation on board to measure,

- Fuel Consumption and Efficiency of each of the propulsion and auxiliary engines

- Electrical Loads and Generator performance

- Vessel’s operational speeds

- Propeller Power

- Shaft line Torsional Vibration.

- we measure the actual performance of the boat’s machinery and stern gear and because we measure to the same International Standards used by the Engine Manufactures we generate an "apples with apples" comparison.

- we verify the Engineering Analysis undertaken in Step 1

The Base line determines how the boat is performing.

Why is this important?

- Because the merit of a repowering solution can be judged based on an accurate knowledge of the base line.

- Accuracy supports financial justifications to lenders and state agencies

Step 3

Specification and Design

From the Baseline we specify and design the optimum solution for the boat considering the owner’s own experience and preferences.

Step 4

Supply, Install & Support - The Optimum Solution – Hybrid Propulsion

Following the design, we can configure and supply the solution as an Integrated package including Wheelhouse Consoles and Power Management Systems.

As an Irish and European company spare parts and technical support are always readily available.